PTS can conduct Feasibility Studies for clients who want to evaluate project initiatives regardless of size or complexity. Whether a client is considering a large scale manufacturing platform decision involving vertical integration or a smaller scale targeted concept intended to improve or expand current operations, PTS has the capability to assist in these evaluations.

Feasibility Studies can vary dramatically in terms of size and complexity. Some examples of initiatives that we have evaluated for our clients include the following:

- Self-Manufacturing of container manufacturing in beverage operations

- Selection of ideal plant location to implement an injection center for preform manufacture

- Review of alternative processing methods for blow molding and filling operations

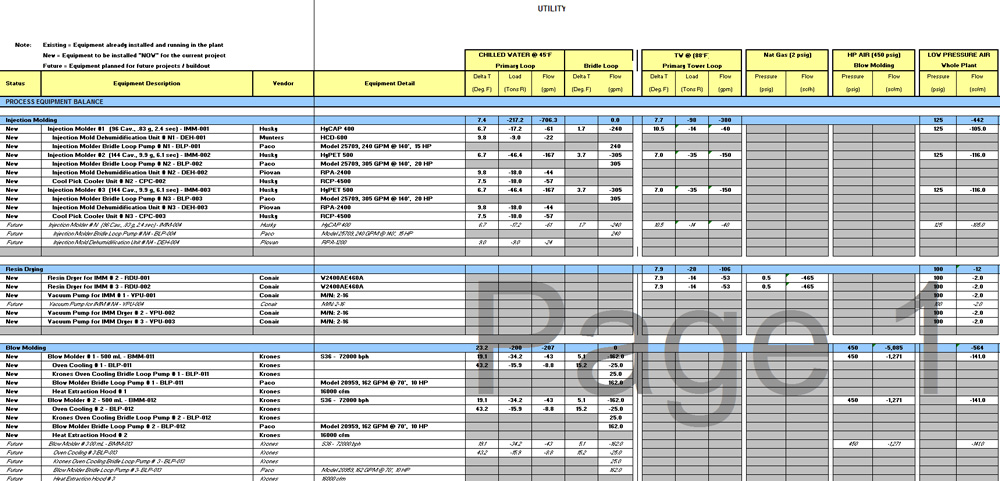

- Utility System approaches to provide optimal efficiency and lowest Total Cost of Ownership

- Review of product handling and packaging layouts and techniques

- Consolidation of manufacturing facilities into a single high-efficiency, high-output facility with recycling and fleet maintenance facilities on-campus.

- Energy conservation projects (utility optimization reducing energy usage and TCO)

- Water conservation

- Nitrogen generation

- Co-gen, tri-gen, quad-gen (CO2 capture) process integration

- Preform manufacturing

- Net-zero carbon footprint

- Elimination of ammonia-based refrigeration where facilities are located near residential areas

In order to conduct an effective Feasibility Study, it is essential to identify all of the variables that will impact the decision and should be considered as part of the evaluation. Accurately quantifying those variables is critical to the process. PTS utilizes System Audits, evaluations of client supplied data, review of vendor technical materials and other alternative methodologies to achieve this goal.

PTS can evaluate the cost of implementation and the anticipated ongoing operational cost saving benefits to help in determining the client’s likely Return on Investment for the initiative being considered.