For many clients, a proposed upgrade to manufacturing operations will be dependent upon the ability of the existing infrastructure to support the additional loads on essential plant utilities. For others clients, the performance of existing manufacturing operations are failing to meet production expectations due to deficiencies in the plant utility systems.

PTS can provide complete System Audits to establish the ‘current state’ of all utilities within a client’s facility. We can also provide targeted System Audits of a particular area if there is a particular area of concern. The goal of these audits is to establish the capabilities and operational performance of these utilities (supply side) as compared to the current and future requirements of the manufacturing operations (demand side).

System Audits can include evaluation of any or all of the following:

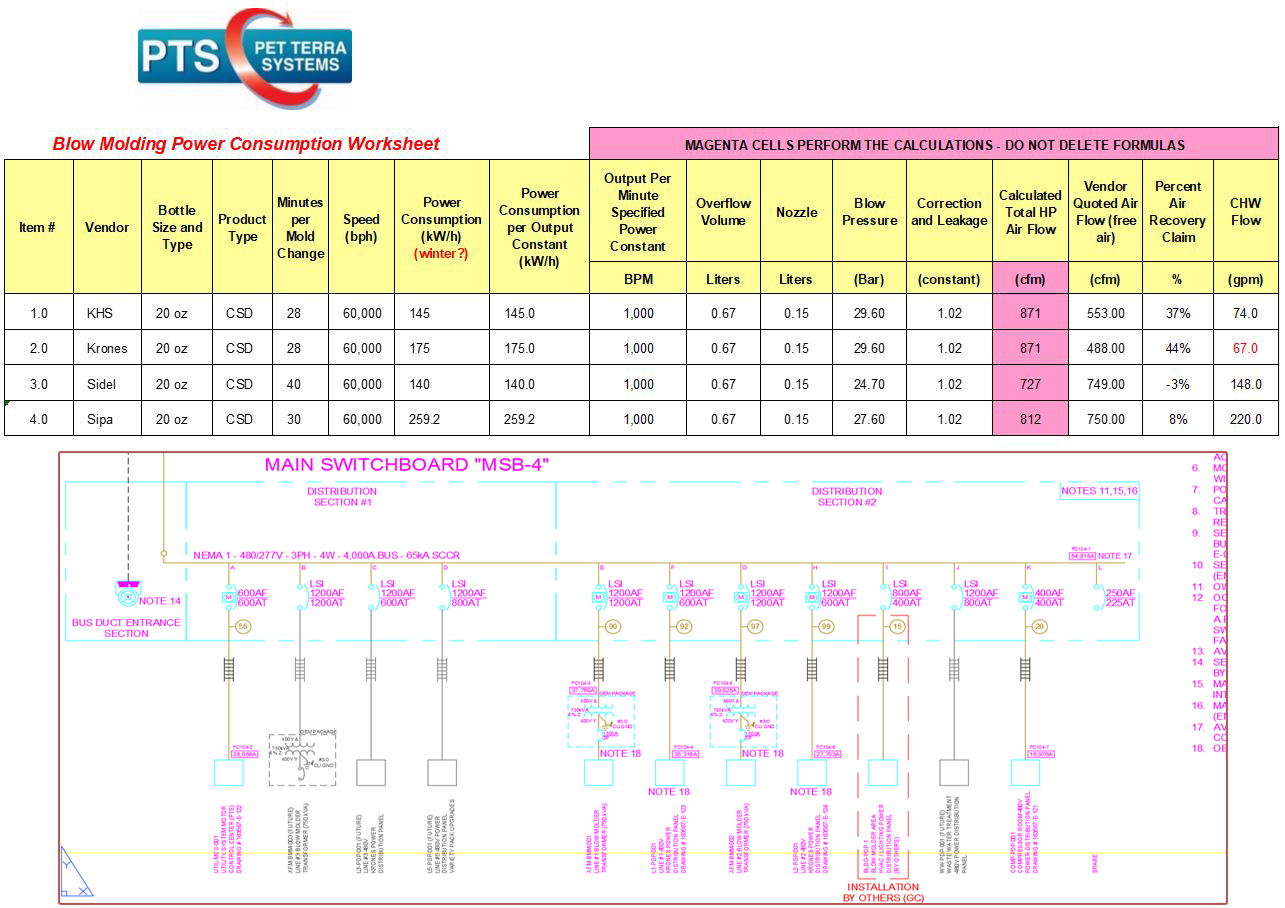

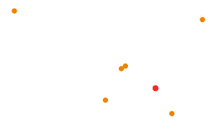

- Power Distribution and Electrical Load Analysis

- Cooling Water System Load Analysis

- Chilled Water System Load Analysis

- Compressed Air System Load Analysis

- HVAC Capabilities Review

- Production Equipment Load Requirement Analysis

- Arc flash hazard analysis

- Arc flash incident energy reduction analysis

- Nitrogen and CO2 system analysis

- HVAC analysis

- Whole facility asset evaluation for mergers & acquisitions

- P&ID, flow diagram, single line diagram generation or updates

- 3D laser scanning and 3D modeling

- Process, utility, and manufacturing energy audits

- Alternative energy integration opportunity audits

Deliverables from System Audits typically include One-Line Electrical Load Diagrams, Electrical Load Summaries, Utility Load Balance and Process Flow Diagrams. These deliverables provide a better understanding of system capabilities and deficiencies of the utility systems and form the basis for any future scope of work and budget to improve these systems as part of a project under consideration.