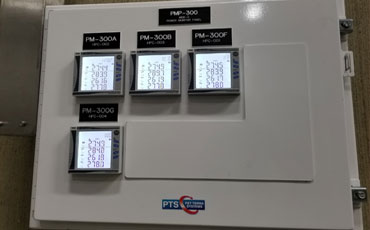

With the growing complexity of clients’ production facilities, including the emphasis on centralized control for utility systems, the controls integration of process systems, and the need for more granular utility usage and cost monitoring (electrical, water, and sanitary sewer), PTS has assembled a highly qualified staff of Controls Engineers to provide these services to our clients.

PTS has the ability to conceptualize, design, implement and support Centralized Control Systems which are able to effectively integrate equipment components from many different manufacturers. Centralized Control Systems provide a single point of interface to manage the many systems operating within a client’s facility.

Control System solutions are customized to a client’s particular needs. Whether the system involves automated control of key equipment components to a predefined sequence of operation, provides health monitoring functionality and data trending, or highly customized and can vary dramatically in terms of size and complexity. Some examples of initiatives that we have evaluated for our clients include the following:

- Centralized control of plant Utility & Process systems.

- Integration of controls into new or existing SCADA or building automation systems.

- Power and utility monitoring that allows accurate Cost Tracking.

- Customized programming to predefined sequence of operation (SOP) to maximize efficiency.

- Support Services for our Control Systems and those supplied by others.

- Control System optimization/updating based upon client requests.

By providing state-of-the-art Control Systems to automate, monitor and trend varied plant operations, PTS allows our clients to focus on the core competency of product manufacture. Our Control Systems are designed to drive efficiency and reliability within critical plant systems. The results minimize the costs of operation and provide the empirical data that helps our clients maximize profitability.